- Home

- Industries

- Electric Vehicle

Electric Vehicle

Innovative, High-Efficiency, and Sustainable Electric Vehicle Component Fabrication

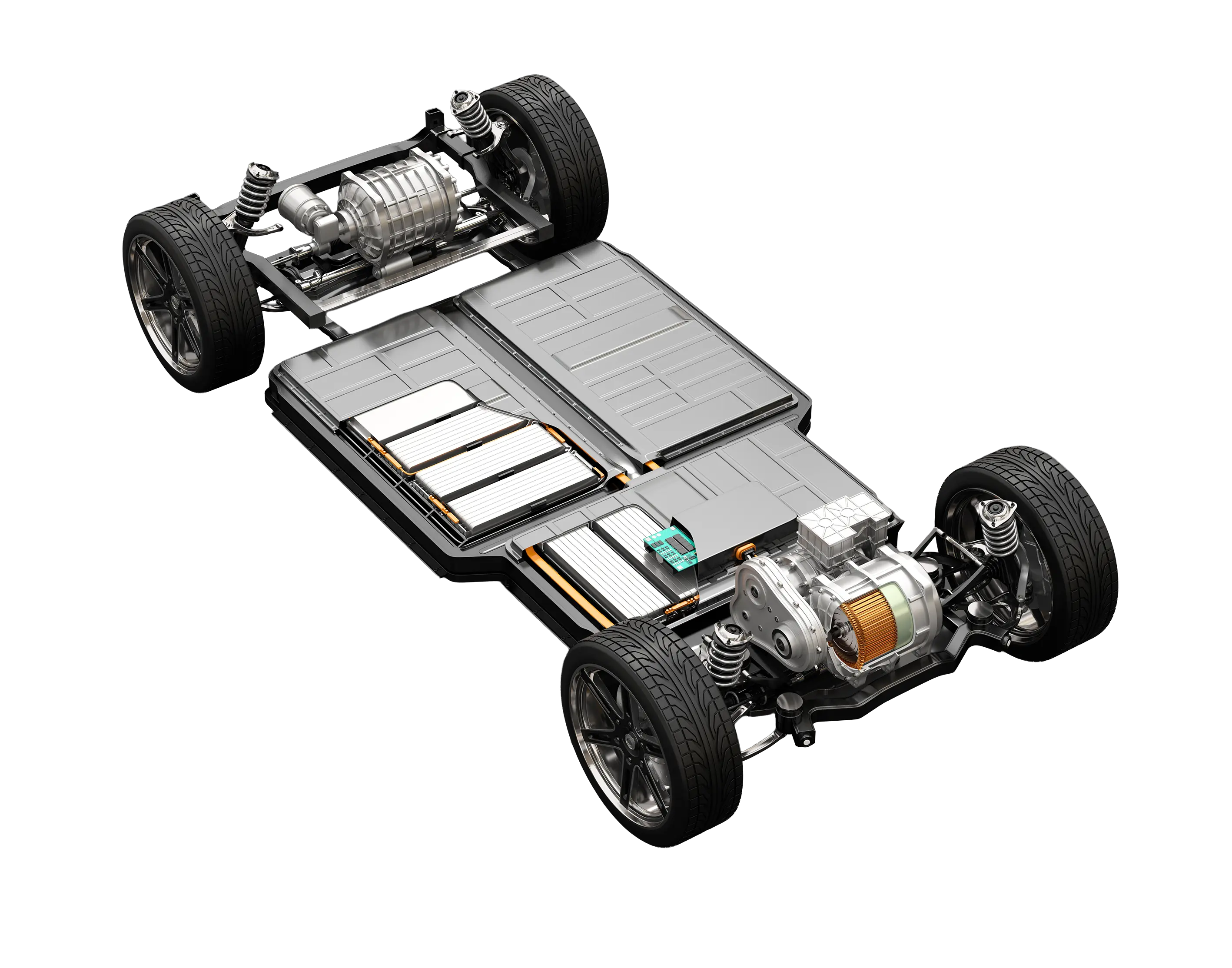

CEIA provides state-of-the-art induction thermal processing systems specifically calibrated for the electric vehicle (EV) industry, addressing the distinctive requirements of battery power modules, power electronic architectures, e-motors, and complex sub-assemblies. Ranging from brazing and structural bonding to interference fitting, thermal treatment protocols, and highly controlled thermal management, our technologies guarantee that EV constituent elements are engineered for optimized performance, extended operational lifecycle, and environmental sustainability.

Initiate a Consultation to ascertain how CEIA can enhance your EV production methodology through cleaner, accelerated, and more dependable fabrication processes.

Advancing Electric Vehicle Fabrication Utilizing Induction Thermal Processing

Battery Tab & Busbar Soldering / Brazing Integration

For the structural joining within battery power modules, involving busbars and copper/aluminum terminal tabs, CEIA's induction heating apparatus ensures high electrical conductivity, reproducible joint integrity, and minimal thermal risk to adjacent cells or insulating media. This is critical for the safety, efficiency, and longevity of the resultant battery modules and packs.

Adhesive Curing & Structural Bonding / Module Enclosure Assembly

EV constituent assemblies necessitate robust, high-precision bonding for module containment structures, encapsulation media, adhesive interfaces, or insulation systems. Induction thermal processing facilitates the accelerated curing and molecular bonding of adhesives with high spatial accuracy, enabling expedited production cycle times without detrimental effects on thermally sensitive materials.

Motor, Stator & Rotor Integration & Interference Fitting

The shrink-fitting of motor housings or the integration of rotor/stator elements mandates stringent dimensional tolerances and stress-mitigated assembly procedures. CEIA's induction solutions provide meticulously controlled interference fitting and component alignment, thereby ensuring the mechanical resilience and optimal operational characteristics of EV e-motors.

Thermal Treatment of EV-Specific Mechanical Components

EV transmission gear sets, drive shafts, and power electronics containment structures require enhanced wear resistance, specified hardness parameters, and precise microstructural characteristics. CEIA systems provide support for superficial hardening, residual stress mitigation, and annealing procedures to meet these advanced material performance specifications.

Core Electric Vehicle Fabrication Procedures

Operational Procedure |

Associated Components |

Technical Advantages |

|

Busbar / Tab Soldering & Brazing

|

Copper / aluminum terminals, battery conductive paths

|

Elevated conductivity, minimal thermal perturbation, reliable joint integrity

|

|

Adhesive Curing & Module Structural Bonding

|

Battery enclosure containment elements, insulating media

|

Homogeneous curing profile, robust adhesion, accelerated assembly cadence

|

|

Superficial Hardening & Thermal Treatment

|

EV transmission gear sets, drive shafts, housing sub-assemblies

|

Augmented resistance to mechanical wear, increased fatigue threshold

|

|

Thermal Management & Containment Structures Assembly

|

Power electronics housings, heat exchange jackets

|

Efficient thermal energy transfer, mitigation of induced thermal stress

|

Strategic Collaboration With CEIA for Electric Vehicle Technological Advancement

From battery pack brazing and module structural bonding to e-motor integration, superficial hardening, and thermal management protocols, CEIA provides precision, operational dependability, and environmentally sound performance for the EV manufacturing sector.

CEIA Technical Competency in EV & Induction Technology

CEIA contributes decades of accumulated professional experience to the EV sector. Our induction thermal processing apparatus is engineered for precision control, procedural repeatability, and energy utilization efficiency, collaborating closely with Original Equipment Manufacturers (OEMs) and Tier-1 suppliers to satisfy rigorous performance mandates. Our Core Competencies Encompass:

- Automated induction brazing / soldering production lines for battery and power electronic components

- Advanced inductor coil design and seamless integration for stator & rotor assemblies

- Real-time thermal parameter monitoring and closed-loop feedback control systems

- Programmable thermal processing profiles, ensuring precise, multi-stage regulation across the entire heating cycle.

Operational Experience and Technical Authority

CEIA has partnered with market leaders in EV production to optimize fabrication methodologies that guarantee reproducible performance metrics, certified quality assurance, and long-term functional durability. Our engineering personnel possess profound domain expertise in managing thermally sensitive materials and complex component integration tasks, thereby contributing to the realization of safer, demonstrably higher-performing EV systems.

Sustainable and Energy-Efficient EV Component Fabrication

Induction thermal processing supports environmentally sustainable manufacturing protocols within the EV sector by offering:

- Localized thermal application with minimal extraneous energy dissipation

- Reduction of the carbon footprint through clean, non-contact heating modalities

- Accelerated production cycle times, diminished rework requirements, and reduced material waste

- Enhanced operational safety and lower pollutant emissions

Through the incorporation of CEIA's induction heating technology, manufacturers are empowered to advance green mobility initiatives, EV operational efficiency, and production sustainability goals.