- Home

- Industries

- Green energy

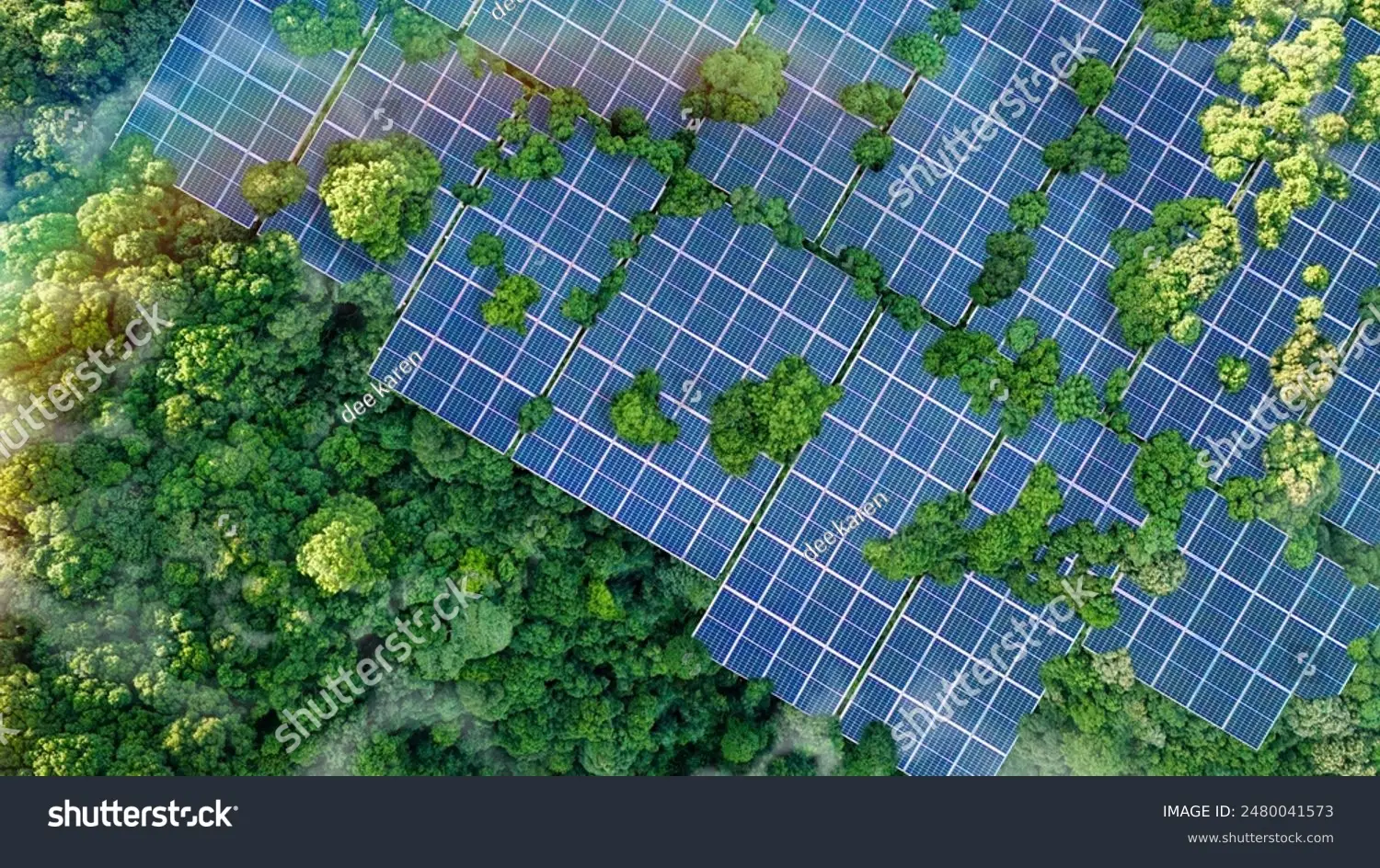

Green energy

The green energy sector is transforming how power is generated, stored, and transmitted, driven by renewable sources such as wind, solar, hydro, biomass, and geothermal energy.

At CEIA, our induction heating technologies support sustainable manufacturing and renewable energy technology, helping you construct resilient, high-performance components like solar panel mounts, power electronics, and hydrogen fuel cell systems.

Request a consultation to ascertain how induction heating can support sustainable manufacturing and renewable energy technology.

How Induction Heating Advances Green Energy & Sustainable Manufacturing

- Clean, efficient thermal processes – Induction heating provides precise, localized heat without combustion. This process is optimal for renewable energy technology where low emissions and high energy efficiency are critical.

- Assists durability in harsh environments – Components utilized in green energy (wind turbine shafts, gear hubs, etc.) encounter extreme conditions. Surface hardening via induction extends fatigue life, wear resistance, and operational performance.

- Supports creating sustainable sources & materials – The utilization of induction heating aligns with sustainable sources by reducing waste, lowering energy consumption, and enabling components to be recycled or reused more effectively.

Key Applications: Green Energy, Power Transmission & Energy Storage

The following details the most relevant applications where CEIA induction heating systems deliver measurable value:

Application |

Parts / Components |

Benefits & Why it Matters |

|

Surface Hardening for Turbines & Shafts

|

Wind turbine hubs, shafts, bearings, raceways

|

Enhances wear resistance and fatigue life. Ensures long-term stability for power transmission within renewable energy systems.

|

|

Pyrolysis

|

Hydrocarbons and biomass

|

Fuel reclamation and refinement of biomass into biochar used in fertilizers and soil improvement.

|

|

Brazing & Joining in Power Electronics & Solar

|

Power electronics, soldering, high-voltage busbars, solar panel mounts, battery module components

|

Strong, repeatable joints with minimal oxidation; critical for efficient electrical performance and durability.

|

|

Shrink Fitting & Assembly of Hydrogen Fuel Cells & Generators

|

Magnet housings, generator rotors, hydrogen fuel cell stacks

|

Precise mechanical fits without compromising sensitive materials; improves performance and longevity in energy storage and hydrogen fuel cell applications.

|

|

Annealing & Stress Relieving

|

Solar panel frames, EV / grid-scale battery casings

|

Reduces residual stresses to avert warping or failure; improves stability for products exposed to thermal cycling.

|

|

Thermal Curing in Battery Manufacturing

|

Cell interconnects, battery tabs, adhesive curing

|

Localized, controllable heat protects sensitive components; supports scalable, clean production lines.

|

Speak With a Professional about your application or green energy needs.

Keywords & Themes We Embrace

We integrate everything from green energy, renewable sources, energy storage solutions, power transmission, to surface hardening and induction heating as core to our product design and service philosophy. Whether you're manufacturing solar panel mounts or developing power electronics for hydrogen fuel cells, CEIA supports your trajectory toward sustainable, efficient, and durable solutions.

Why Choose CEIA for Your Green Energy Needs

- Sustainable Manufacturing Focus: We design systems to support renewable sources and energy storage solutions while minimizing environmental impact.

- Expertise in Renewable Energy Technology: From hydrogen fuel cells to solar and wind power, our induction heating and thermal processes are built for cutting-edge applications and rigorous engineering requirements.

- Reliable Components for Power Transmission: Ensuring robust, durable parts in power electronics and transmission infrastructure helps maintain system integrity over long service lifetimes.