CEIA SpA participated in the international trade fair Blechexpo, which took place in Stuttgart (Germany) from October 21 to 24, 2025. The company, a key player in the design and production of induction generators, was present with colleagues from CEIA INDUKTION in Hall 9, Stand 9229. The participation allowed the company to meet professionals and potential customers in the metalworking sector and to present the complete range of Power Cube Family induction generators for the heat treatment of metals.

- Home

- Blog

Blog

All

CEIA presented the Power Cube Family range at the Blechexpo trade fair in Stuttgart

CEIA Induction Heating Solutions for the Fastener Industry

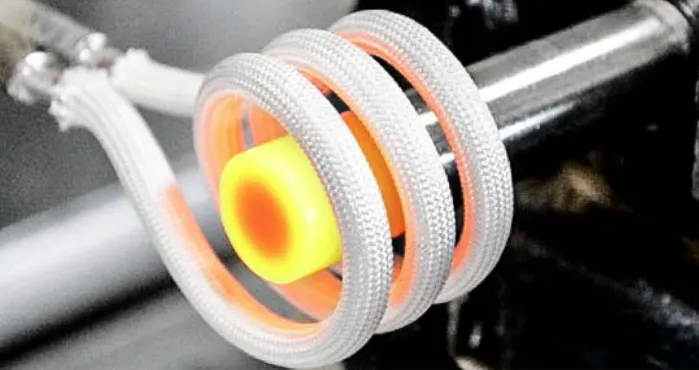

Induction heating is widely used in the fastener industry to ensure precision, quality, and efficiency. By heating metals to controlled temperatures, the material’s malleability is maximized without causing re-crystallization, grain growth, or metallurgical fractures. This enhances quality, increases productivity, and extends machine life.

How to Transition to Induction Heating for Shrink Fitting

Explore how to upgrade your shrink fitting process with induction heating. Discover the benefits, essential steps, and key considerations when transitioning from traditional methods.

What Is Shrink Fitting and How Does Induction Heating Help?

Shrink fitting joins two parts by heating the outer piece so it expands and fits over the inner one. As it cools, it contracts and grips tightly, creating a strong, precise fit without adhesives or fasteners. Compared to slower methods like ovens, induction heating is faster, cleaner, and ideal for modern production.

Precision Forging Solutions Powered by Induction Heating

Induction heating is gaining momentum in forging for its speed, accuracy, and energy efficiency. It delivers targeted, repeatable heat for billets, bar ends, and parts. This blog explores how it helps manufacturers increase productivity and reduce costs.

The Aerospace Advantage of Induction Surface Hardening

Induction surface hardening provides aerospace manufacturers with a precise method to enhance durability in components such as landing gear and shafts without adding weight or causing distortion. It treats only the surface, improving wear and fatigue resistance while maintaining tight tolerances.

Precision Matters: Why CEIA Induction Heating Systems Are Ideal for Crystal Growing

Discover why CEIA induction heating systems are ideal for crystal growing. With precise temperature control, stable output, and energy efficiency, they support high-quality crystal production for semiconductors, optics, solar, and research applications.